Whitney Overview

The most problematic axis on the Whitney systems is the refurbishment of the X-Axis ball screw which moves the sheet material. This screw is a Japanese type assembly with an external rotation bearing. There are no provisions on this machine to lubricate the ball screw. Meaning that after 3-5+ years of operation, the screw is often worn to the point of destruction. What many Whitney Plasma/Punch owners do not know, is that there ball screws are rebuildable at a fraction of the cost of purchasing a new one. Without the lead time waiting for removal, core exchange, shipping, and reinstallation. The rebuilding of the X-Axis in your machine, will typically take Ballscrew Guys 5-6 hours.

The Y-Axis and V-Axis are far for simple to rebuild and repair. But because these are exposed ball screws without protective covers, they are often contaminated quickly. Reducing the service life and accuracy of the ball screw. It is not uncommon that in high output and volume shops, that these screws need to be refurbished annually.

The most problematic axis on the Whitney systems is the refurbishment of the X-Axis Ballscrew which moves the material. This screw is a Japanese type assembly with an external rotation bearing. There are no provisions on this machine to lubricate the ballscrew. Meaning that after 3-5+ years of operation, the screw is often worn to the point of destruction. What many Whitney Plasma/Punch owners do not know, is that there ball screws are rebuildable at a fraction of the cost of purchasing a new one. Without the lead time waiting for removal, core exchange, shipping, and reinstallation. The rebuilding of the X-Axis in your machine, will typically take Ballscrewguys 5-6 hours.

The Y-Axis and V-Axis are far for simple to rebuild and repair. But because these are exposed ballscrews without protective covers, they are often contaminated quickly. Reducing the service life and accuracy of the ballscrew. It is not uncommon that in high output and volume shops, that these screws need to be refurbished annually.

It's always nice to have the table removed when we service the V-Axis. Regardless, we are not afraid to crawl "into the hole" to service this ball screw.

The X-Axis of the Whitney Plasma Punches do not have any system for auto lubrication. This ball screw is a sealed NSK external rotation bearing type. It gets packed with lubrication upon assembly and is left to run. It is critical that these assemblies are refurbished at least every 2-3 years at a minimum. This will prevent permanent damage to the screw.

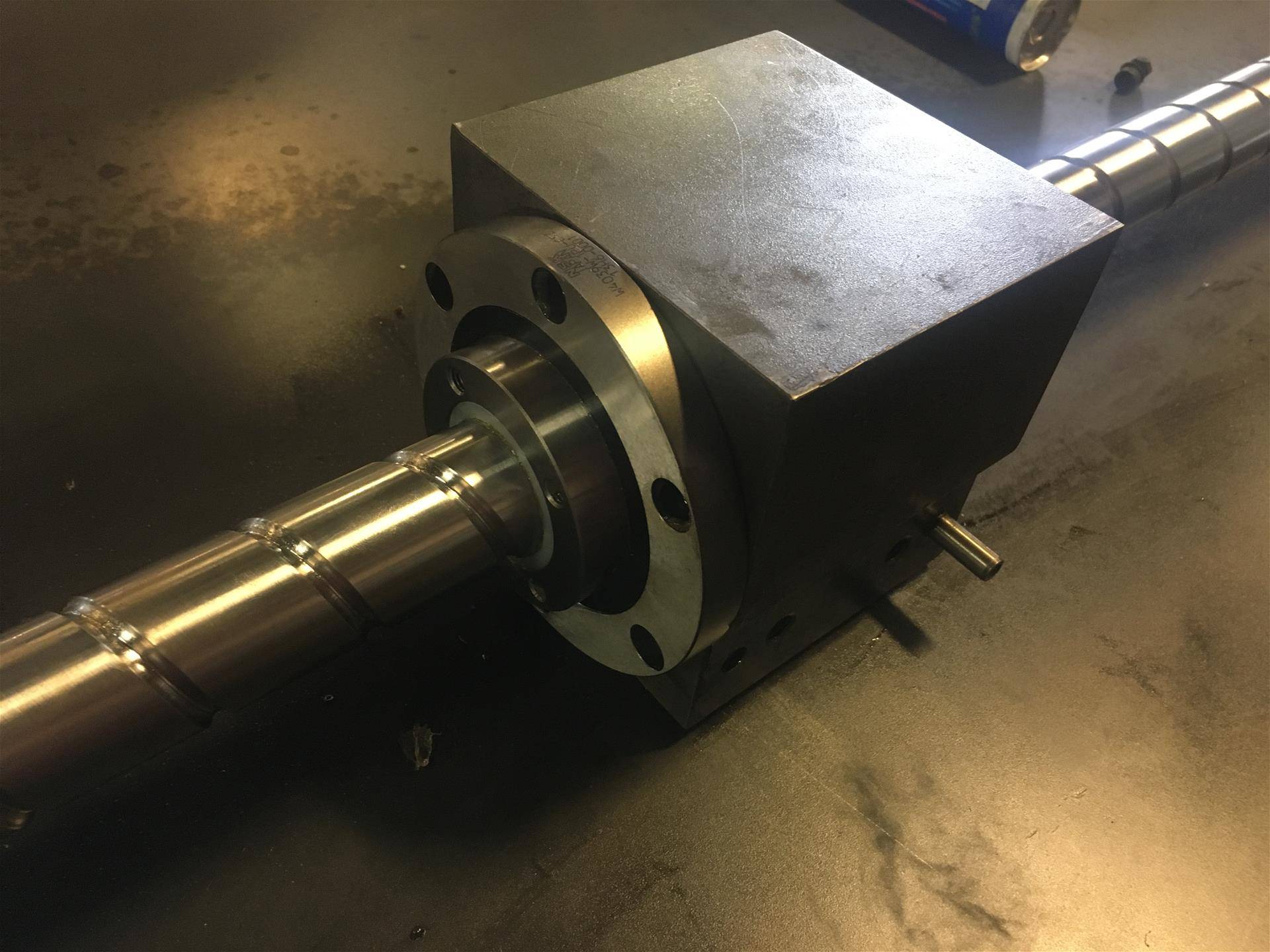

Rebuilding the ball screw assembly of a Whitney. This is the assembly of the rotation bearing assembly that connects to the belt/pulley drive system.

These need to be cleaned, flushed, and regularly lubricated.

Pulling the entire X-Axis of a Whitney Plasma punch for full refurbishment. Typically we can rebuild this axis of ball screw in the machine. But, because of the lack of lubrication delivery to this axis, we are designing upgraded seals to increase the working longevity of this screw.

Which one is original OEM, which one was made at a local machine shop for 1/3rd the cost?